How To Make A Product Specification Sheet For Your FBA Product // Step-By-Step Guide

How to create a product spec sheet that ensures you get the exact product you want from your supplier!

If you can imagine a product, a factory can probably build it. China and Vietnam have a seemingly endless number of manufacturers that can make various products. But how do you know the supplier makes your product exactly as you want? With a well-written product specification sheet. While it takes several steps to make your idea into a product, one of the first things you must do is create a product specification sheet. Cosmo Sourcing has simplified this process into our simple sourcing, which has four steps: Plan, find, make, and ship.

What Is A Product Specification Sheet?

A product specification sheet is a document that details your product. It should provide a broad overview and numerous sections detailing the components you want to deliver in a product. A good product sheet is concise yet thorough, containing everything the product needs without the fluff. Your manufacturers will receive the product specification sheet and use it as a reference for quotes and your product’s manufacturing. Even before your product is made, a manufacturer must have specifications to give you an accurate quote.

A product specification sheet will also be used later when you order samples. We use a modified product specification sheet as our sample evaluation form. In the sample evaluation process, which we’ll discuss later, we create a checklist from the product specification sheet and go through it line by line to check each detail on the sample to see what was requested.

One thing to keep in mind when creating a product specification sheet is that manufacturers often cut corners. Be mindful of this and consider the details you want to highlight to ensure quality. You need to know that there is no such thing as a supplier that will get 100% of the product and details perfect, so you need to know what is acceptable quality to you and fill in your product spec sheet accordingly.

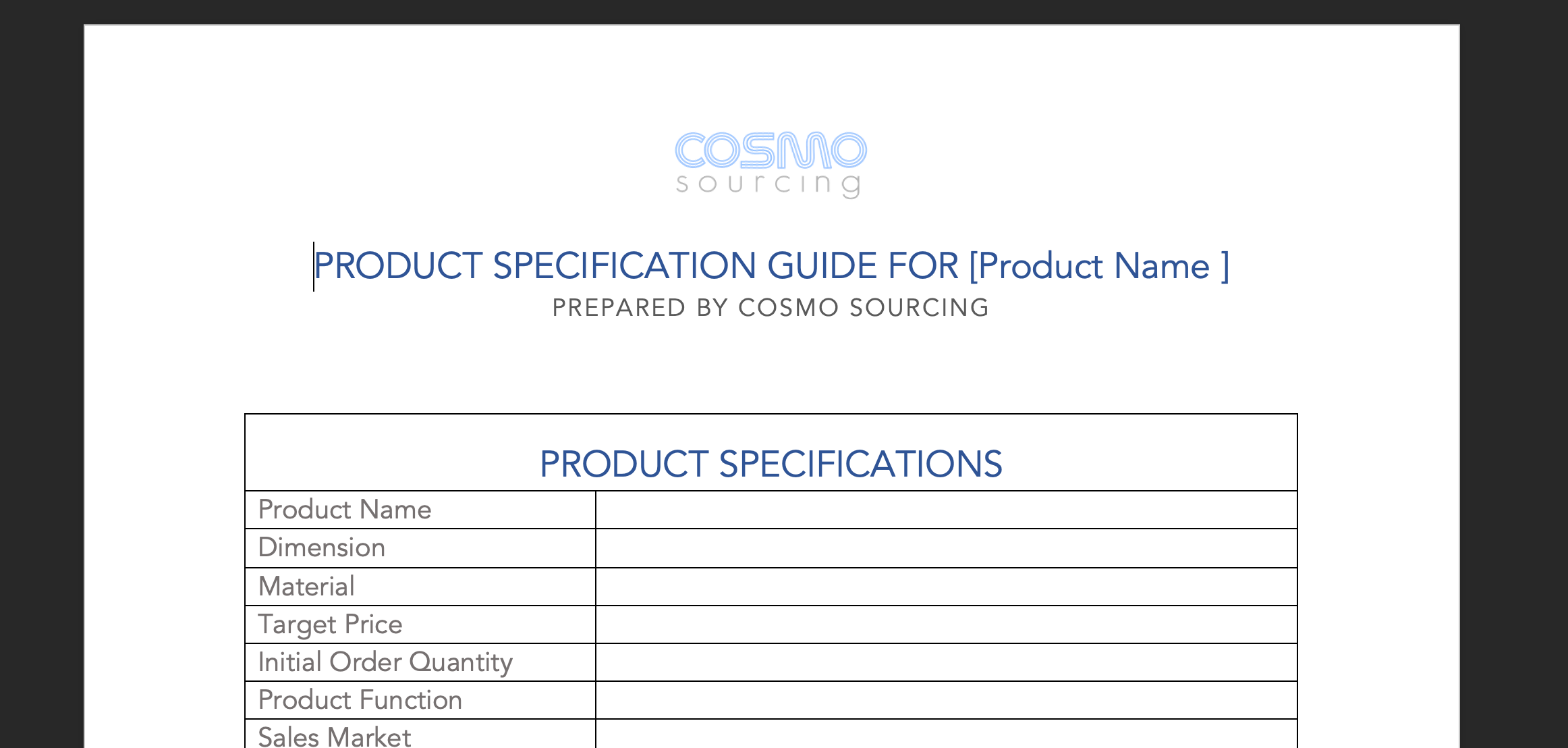

Here’s a free Product Specification template!

If you’re unsure what a product sheet should look like, please download our template. Our product spec sheet is a basic template, so you should heavily modify your template to suit your product. Regardless, fill in the email, and we’ll send you the template we use for our projects!

Enter your email below!

How To Make A Product Specification Sheet

We’ll go over how to make a product spec sheet, but there should be a reasonably well-structured outline for the most part. These are the main sections needed for a standard product spec sheet. This section follows our template and goes more in-depth with instructions for each part. Please follow the link, get the template, and then follow along and fill in each part as instructed. If you do not have the template, create a simple outline with each section below.

Product Summary

Most people overthink this one, but it helps to keep it simple. Just use a few sentences to a paragraph to describe your product, how the customer will use it, and some other details. You may want two paragraphs for more complex products, but beyond that, you’re just going to bog down the reader. Save the details for later; this needs to give the recipient the product’s general idea.

Product Specifications

These will be your product’s raw stats: weight, dimensions, colors, materials, Estimated order quantity, Target price, IP rights, intended market, etc., should be here. This is mostly organized in a bulleted list or a table. This part is focused on your product's raw stats.

Bill Of Materials

The Bill of Materials, again, is a bulleted list. For this part, state the exact materials that the manufacturer will use. For some items, simply stating strong Fabric” is fine, but you want to be specific for most, such as stating 60D Nylon as the fabric. You also want to run down every material the manufacturer will use in your product. Most factories specializing in your product will already have everything in the house, but sometimes, they need to order raw materials.

Reference Photos

Photos are one of the most essential parts of your product spec sheet because most people will only look at this part. Remember that English is likely their second language if you are sourcing from China or Vietnam. Photos, however, transcend language and can be understood by almost everyone.

You will need two types of photos. The first is bare photos of the product if it exists. If the product does not exist, sketches or mock-ups work well. The second is technical diagrams that show the dimensions of products.

Packaging

Most clients overlook packaging when it comes to products. Yet packaging is essential to the product experience and branding. Therefore, it is necessary to protect your product when it ships from China to a warehouse and from a warehouse to the customer.

You also need to specify the master carton dimension. The Master Carton is the big box that will carry your smaller items to the States. If you are ordering 1,000 units of a gizmo, it’s crazy to ship each item separately from China to the US. So, instead, most people place the units into a larger box, perhaps 50-200 units per box.

Product Compliance Standards

To be manufactured and imported into their respective countries, many products must meet specific compliance standards. Figuring out compliance standards can be tricky; we’ll review that later. Types of Compliance standards to look out for are any regulatory approval needed by a country, which is up to the buyer to obtain, and factory certifications, such as ISO standards, are up to the supplier.

What Otherwise Should Be In A Product Specification Sheet?

There isn’t a single good template for a product specification sheet, as each product is different and has its attributes. Nonetheless, here is a list of potential points to cover:

What is the purpose of your product?

What material do you want your product made of

Dimensions

What features do you want it to have

Waterproof

Durability ratings

Compliance standards

What Color(s) should the product be?

Pantone color codes are universally accepted color standards, so be exact if necessary.

What packaging do you want?

What standards does the product need to meet?

Validation is figuring out what compliance standards are necessary for a product on a major product.

Pictures

Diagrams and graphics

The wording should be short and to the point. Pictures are also a great way to show what product you want to be made. You can find pictures of existing products, details, or a prototype you have made. Pictures and other graphics examples are one way to ensure that something doesn’t get lost in translation.

Draft The Product Spec Sheet

At this point, you should take the outline and have a very rough draft. You must go through and edit about three times to get an excellent product spec sheet. This build will help if you continue researching and learning more about your product. For the most part, use our outline, as it covers most products’ basics.

At this point, you should have everything you want in your product; the next step is adding everything your product needs.

Learn As Much As You Can About Your Product

When you learn about your product, you need to focus on how it’s manufactured. The first time you add information, it tends to be what you want from a product, and the next step is learning as much as possible about your product. Fortunately, we live in the information age where all the resources you need are at your fingertips.

Learn About How Your Product Is Manufactured

When you make a product spec sheet, you design it for manufacturing. This step ensures that your product is grounded in reality. Many people have fantastic ideas for products that sound great on paper but are difficult to manufacture. You can find YouTube videos of the manufacturing process for many products and get a good idea; for others, you may need to dive deep into industry publications.

Look Up Product Details On Amazon And Alibaba.

This goes in from the tip, but the easiest way is to find similar products on these or other websites and copy or paste them more or less. Ensure the product is identical or similar to yours and adjust as needed.

Learn About Product Certifications

When looking at products on websites, you’ll notice that they have various certifications. The easiest way to start is to look at what certifications are included in Amazon’s description. But ultimately, finding the exact certification is a complicated process. We go over these in more detail in our blog about Tariffs and regulations here!

Custom Designs Often Need Custom Tools

Creating a custom product is an excellent way to ensure your product stands out in a crowded marketplace. Many of our clients request custom designs, which we happily help them with. That being said, you must understand that customizing times often requires more upfront costs. For many products, you need to have a mold made; for other projects, we need to have a design made on a computer, both of which require a significant upfront cost. The good news is most of these costs are one-time costs. The higher the upfront, one-time cost, the more product you need to recoup the cost.

Tooling

Tooling is the process of acquiring the machinery, molds, design files, and everything that is needed to make your product. When you vet factories, you must ensure they have the equipment; for the most part, they will let you know, but it’s important to double-check. The best way is to visit in person, but if you cannot, hire an inspection company to do it for you.

Molding

Molding is one of the most common items we work with; we need to make a mold for many products. The most common mold is used in plastic injection molding. The molding process involves creating a cast that the machinery can inject with a liquid that hardens into a shape. Most molds are metal, and a good one can cost a few thousand dollars. However, once it is made, you can often use the product spec sheet for years.

CNC, 3D Printing, and more

3D Printing is more complex than people think; a trained individual must design a digital model using specialized software. They then must upload the file to the printer and let it run. CNC works under a similar concept; however, the machine carves the object from existing material, while a 3-D printer creates it from scratch. Designing files and digital models are similar, so expect to pay someone to do this if you need this for your product.

Please Make It So It Can Be Manufactured.

In the previous step, you should have done a significant amount of research on how it’s manufactured. Now, you should read through your details and adjust them to make them. You will take off and adjust features most of the time, but you may learn to add or make something you didn’t know was possible. Those times can

Regardless, it would be best to remember that the more steps it takes, the more expensive it is. So, for cost-conscious people, you want to ensure that your product is as easy to manufacture as possible. Ideally, you would also want the product made in just one factory with no outsourcing parts. This means you must make a product that a single factory can make and understand.

You should review your product sheet again and adjust the desired features to make it a supplier to manufacture or add the features you learned in the research.

Pictures

A good product spec sheet has many pictures, illustrations, and diagrams that show exactly what the product should look like. As the old saying goes, a picture is worth a thousand words. The more pictures you include, the better. If your product or a prototype has already been made, include photos with measuring tapes so the factory can know the dimensions. If you want an exact color, include color swatches so that they have an exact reference. Take photos of the details that you want, such as stitching. Feel free to use a basic imaging program to add arrows and text boxes to the highlight feature.

Finish The Product Spec Sheet

First, you made the product spec sheet with everything you wanted; then, you made it with everything you needed; now, you must have everything.

By now, you should have everything already in the product spec sheet and modify it so the factory can make it. Then, it would help to polish it so it is clean and readable. Keep technical details as is, but for the summaries and other parts, use simple English easily. Remember that almost all the salespeople and engineers are not native English speakers and often will use translation software to read it.

Frankly, you’ll likely update this several times through the sourcing process. It’s not uncommon for us to make multiple revisions until the final manufacturing stage.

What Format Should A Product Spect Shet Be In?

Most Product spec sheets are created in Excel or Word, but you should send them to your potential suppliers as a PDF. The reason is so the supplier does not alter it, and you can ensure there aren’t any formatting changes when emailed. Keep in mind that when you send out a product spec sheet, it will likely be shared at any time by email and printed among staff at the supplier. Include page numbers, a header or footer with your contact info on every page, and a page number.

Sourcing Kit // Take Control Of Your Sourcing!

Ready to go beyond creating a product spec sheet? Transform your entire sourcing process with the Sourcing Kit! Our all-in-one toolkit offers much more than templates. You'll get access to comprehensive resources, including detailed contract templates, self-guided courses, practical scripts, and expert guidance to manage every step of your sourcing journey.

Don’t stop at the basics—empower yourself to handle every aspect of sourcing confidently and easily. Click here to sign up for the Sourcing Kit today and unlock the full potential of your sourcing strategy. Your journey to mastering global procurement starts now!